Solidworks Design

Let us bring your idea to Reality! With our state-of-the-art design software, no details will be missed. We can design 3-D models and drawings of your project from start to finish. This keeps everyone on the same page and allows you to visualize what you are getting before we begin.

PythonX Beam Processing

Material conveyance and automated cutting means projects can be completed faster, saving you time and money. The system uses advanced software and sensors to ensure high precision, reducing the risk of errors and rework. Additionally, only one operator is required to run the machine, reducing the need for manual labor and labor costs. With faster project completion times, customer satisfaction can be improved, and revenue can be increased. Finally, the PythonX Structural system can fabricate a wide range of steel profiles and shapes, expanding the capabilities of steel fabricators and allowing them to take on a greater variety of projects.

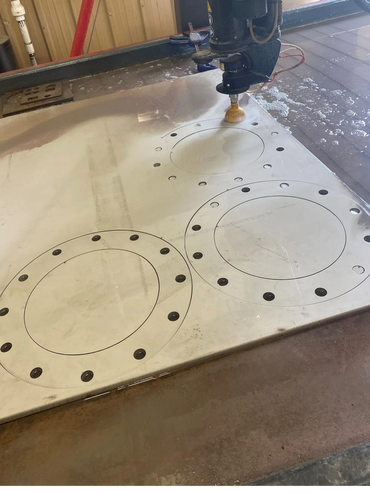

OMAX 5 axis cnc waterjet

Precision cutting with minimal heat input.

This is possibly the most versatile CNC machine on the planet, with accuracy as low as .005" and features such as part beveling and taper compensation, we can insure quality cut parts time after time. This machine uses a 60,000 PSI jet stream to slice through materials up to 8" thick including:

- mild steel

- stainless steel

- aluminum

- stone

- glass

- rubber, plastics, and much more!

Call us today for more information, or send us your cut files for a quote! We readily accept .DWG and .DXF files and all solidworks files.

High definition CNC Plasma

Messer produces some of cleanest edge quality on the market. This machine is capable of producing a high quality cut on aluminum, stainless steel, and mild steel up to 1.5" thick. With the speed of this machine we are able to maintain short lead times while producing superior products.

This machine also offers etching features using low amperage plasma arc to allow for layout marks and labeling of parts. This eliminates head-scratching and streamlines the process when it comes time for assembly.

The bed size on this machine allows for cutting of parts up to 60" wide X 120" long

Send us your cutting files today for a quote! We readily accept .DWG, .DXF and all solidworks files.

350 ton and 200 TON CNC PRESS BREAK

Bending and forming eliminates excessive welding which speeds up the fabrication process and reduces warping or distortion of materials, making an overall superior product.

From simple 90 degree bends to multi-step sequence bends to create unusual parts, the possibilities are endless.

Plate ROlls

We have 3 different size plate rolls capable of rolling up to 10' of 1/2'' and 4' of 3/4'' mild steel

other equipment

Mobile Welding Skids

Piranha 50 ton ironworker

Hydmech VW18 band saw

We have 16 mobile welding rigs with oxy/acetylene torches ready to provide field services.

Hydmech VW18 band saw

Piranha 50 ton ironworker

Hydmech VW18 band saw

Our Semi-Auto Bandsaw is capable of cutting materials or bundles of materials up to 22" tall X 18" wide

Piranha 50 ton ironworker

Piranha 50 ton ironworker

Piranha 50 ton ironworker

Our 50 ton hydraulic Ironworker is capable of cutting, notching, bending, and punching holes in various types of steel.

Hydraulic plate shear

Miller Dynasty AC/DC (high frequency)

Piranha 50 ton ironworker

This machine can shear sheets of plate in minimal time up to 1/4" thick and 10' long

Miller Dynasty AC/DC (high frequency)

Miller Dynasty AC/DC (high frequency)

Miller Dynasty AC/DC (high frequency)

We currently have three miller dynasty welding machines set up to weld aluminum TIG. Two of these machines are mobile for field services.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.